Featured Systems:

Project Type:

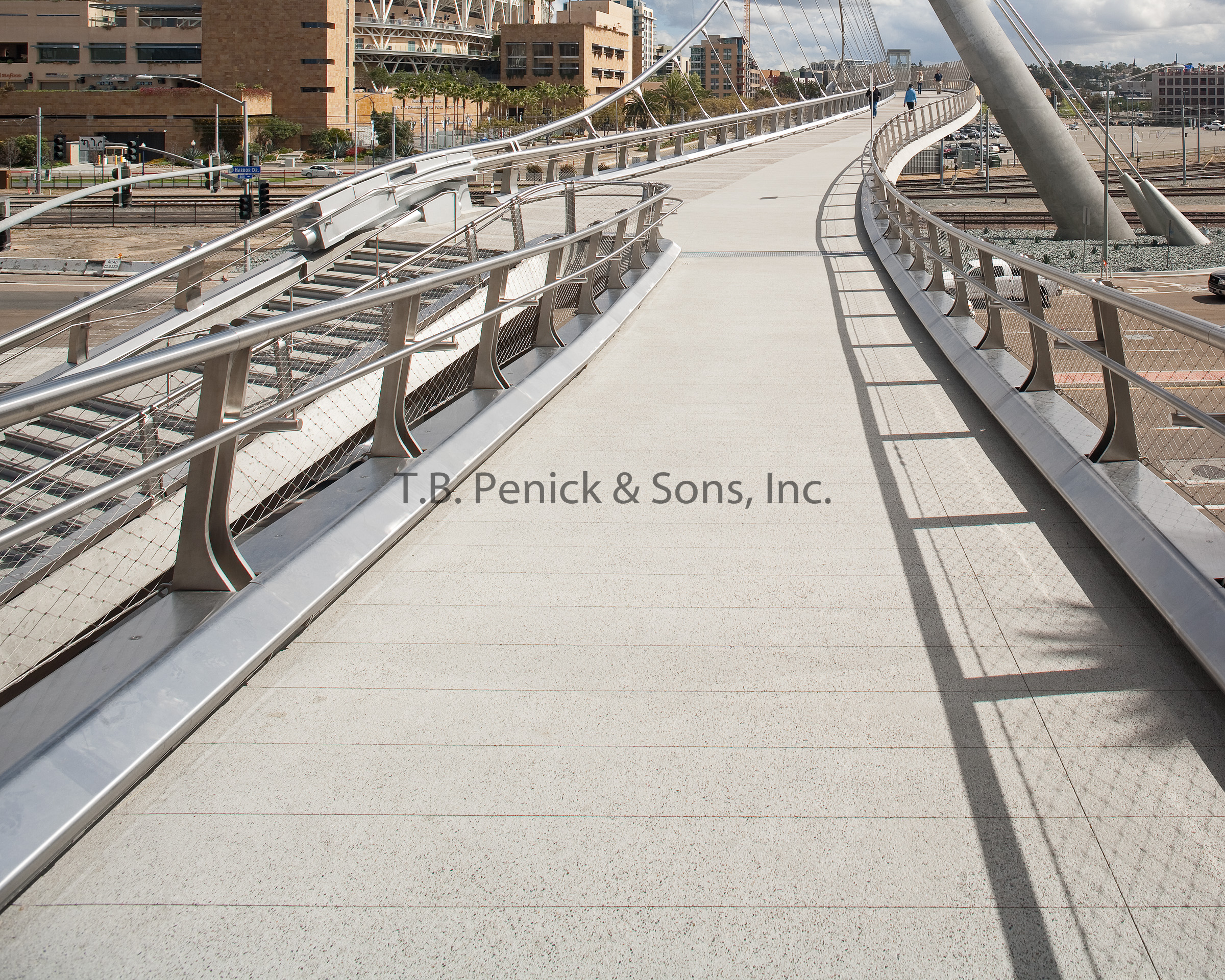

Harbor Drive Bridge

Project Information : Downtown, San Diego, CA

Client : Safdie Rabines Architecture

Awards : ACI Judges award 2013

In downtown San Diego, you’ll find an abundance of the Caroll Canyon exposed aggregate finish, a finish dictated by the city’s redevelopment agency, Centre City Development Corp. (CCDC). Now, that finish also appears on the Harbor Drive Pedestrian Bridge, a graceful structure that carries residents and visitors over San Diego’s Harbor Freeway.

San Diego-based Safdie Rabines Architects, the firm responsible for the bridge’s design along with San Francisco-based T.Y. Lin International, selected the Caroll Canyon exposed aggregate finish and a quarried stone sand finish for the bridge deck. Reyes Construction, the general contractor on the project, asked San Diego-based decorative concrete manufacturer and installer T.B. Penick & Sons Inc. to recreate these two paving finishes, but in topping form. The result: T.B. Penick & Sons Specialty Topping System, a poured-in-place system the company developed especially for the bridge.

“The goal was to match CCDC, which has specific paving in downtown San Diego,” says Chris Klemaske, project developer for T.B. Penick & Sons. “Achieving both finishes in a 3/4-inch topping and, in addition to that, on a bridge structure was a challenge.”

The 550-foot-long bridge spans the waterfront area of San Diego and is one of the world’s longest pedestrian suspension bridges. The bridge is curved and supported by slanted cables on one side, creating a shape that mimics that of a sailboat, Klemaske notes. The bridge is owned by both CCDC and the Unified Port of San Diego.

The walking surface holds perfectly aligned saw cuts that define squares and rectangles, and surface textures and colors vary from a grainy, dark beige to a smoother, pale beige. Architects say T.B. Penick & Sons’ topping gave them the leeway they needed during the design process.

“The concrete topping used on the Harbor Drive Pedestrian Bridge was used due to the material’s thin section and inherent light weight,” says Eric Lindebak, principal at Safdie Rabines Architects. “This material also allowed us the flexibility to vary the color, texture and scoring patterns in the horizontal plane that provide necessary scale, refinement and relationship to the bridge geometry.”

Workers had to grind down some areas of the bridge’s surface to allow for the 3/4-inch topping, Klemaske says. Then, they installed approximately 6,600 square feet of topping material in small, controlled pours. Achieving superb precision was the biggest challenge installers faced, she adds.

“If you look at the span of the bridge, you’ll see that those control joints in between each pour and the saw cuts had to be perfect,” Klemaske says. “Being precise was so critical.”

The bridge opened in early 2011 and has been met with praise, including several awards. “It looks beautiful,” Klemaske says.